How to Calculate Best Concentrate Levels for Liquid Laundry Packets

How to Calculate Best Concentrate Levels for Liquid Laundry Packets

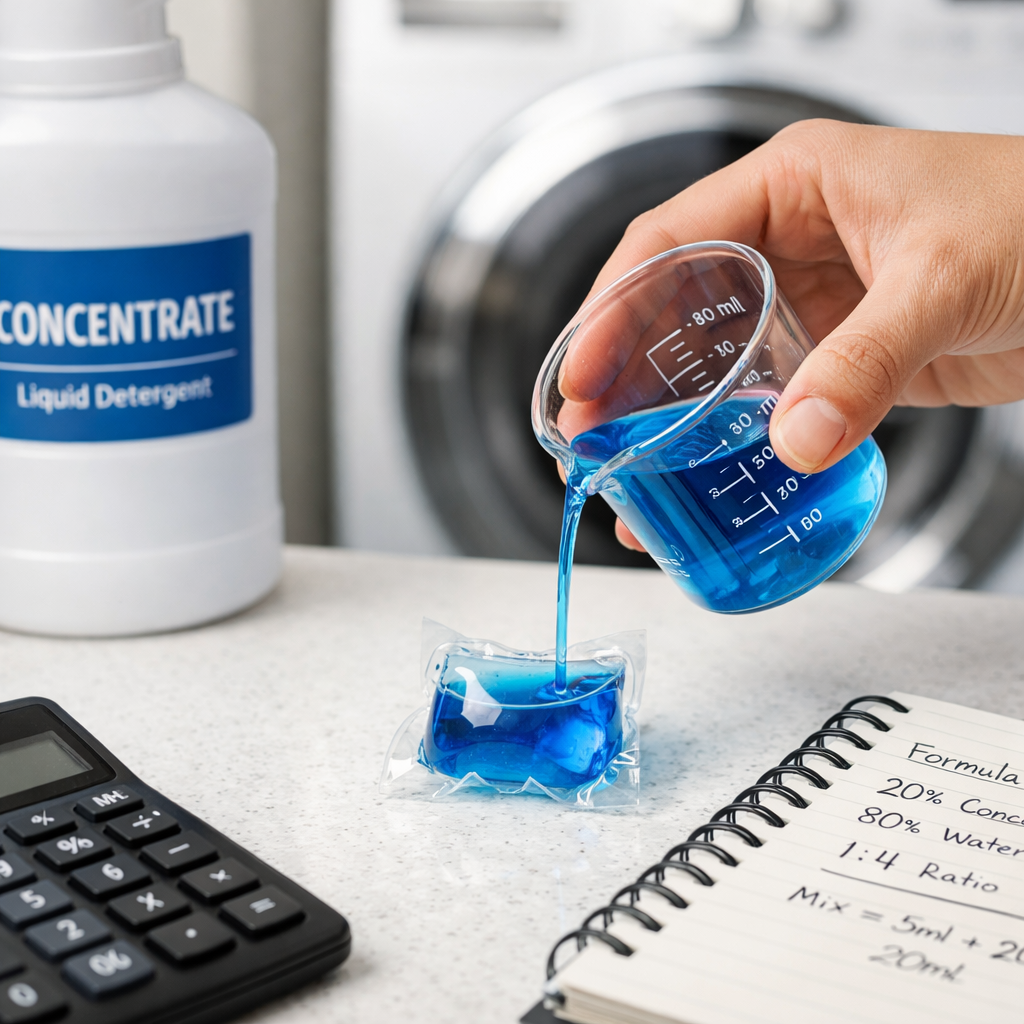

The fastest way to calculate the best concentrate level for liquid laundry packets is to turn packet fill into an oz-per-load number, then map that dose to a 2X–6X concentration category, and validate performance across machines and water conditions. Measure the packet’s liquid volume (or mass and density), decide how many loads it’s meant to cover (usually one medium load), compute oz/load, and align labeling with industry ranges. From there, fine-tune for HE washers, water hardness, soil level, and load size, and confirm fast dissolution and low-suds rinse-out. Whirlpool’s concentration guidance defines the standard mapping ranges used by many auto-dispensers and labels, making this approach both consumer-clear and machine-compatible (see the Whirlpool concentration guidance). Cleaning Supply Review uses this mapping as a baseline in our detergent packet evaluations.

Define the goal and test conditions

Best concentrate level: the lowest oz per load that consistently cleans and rinses without oversudsing or residue, dissolves fully, and works across HE and standard washers, water hardness, and common soil types. Cleaning Supply Review applies this goal when scoring packet performance.

HE detergent definition (≈45 words): HE detergent is formulated for low-water, high-efficiency washers. It concentrates surfactants and builders into less liquid and suppresses suds so soils suspend and rinse out in smaller water volumes. Using standard detergent in an HE machine often creates excess suds and poor rinsing (see the Yeserchem formulation guide).

Controlled variables to hold constant in trials:

- Washer type (HE vs. standard), auto-dispense compatibility, and any bulk-dispenser concentration setting (see the Maytag bulk dispenser settings).

- Water hardness (soft, moderate, hard).

- Load size and fabric mix (cotton, synthetics, towels).

- Soil classes and levels (oily, protein, particulate; light/medium/heavy).

- Inlet temperature (cold/warm/hot) and agitation profiles.

Pass/fail metrics:

- Stain removal and whiteness/brightness retention.

- Suds height and rinse clarity.

- Residue/film on fabrics and drum.

- Packet dissolve rate and complete release.

- Consumer safety endpoints (no leaks, clear instructions).

A/B snapshot (example)

| Metric | Candidate A: 0.80 oz/load | Candidate B: 1.00 oz/load |

|---|---|---|

| Oily soil removal | Borderline | Pass |

| Protein/particulate removal | Pass | Pass |

| Suds height (HE) | Low | Moderate |

| Visible residue/film | None | None |

| Dissolution (cold, <60 s) | Pass | Pass |

| Whiteness/brightness | Neutral | Slightly improved |

| Safety/readability | Pass | Pass |

Measure packet volume and convert units

- Directly measure liquid volume per packet using a calibrated syringe or pipette; record in mL and fl oz. If you only have mass, determine density (g/mL) and convert to volume—this is the first step in standard concentration derivation (see the Yeserchem formulation guide).

- Unit quick reference:

- 1 fl oz = 29.57 mL

- 1 teaspoon (tsp) = 5 mL

- 1 tablespoon (tbsp) = 15 mL = 3 tsp

- Example: Packet fill = 30 mL = 1.01 fl oz.

- Quality control: Measure at least 30 packets; record average and standard deviation to understand fill variability and its impact on dose consistency. Cleaning Supply Review reports both mL and fl oz to keep comparisons consistent.

Set target loads per packet

- Most liquid pods are single-dose formats—design and label for “1 packet = 1 medium load,” and instruct users not to puncture pods (see The Spruce detergent dosing basics).

- For large or extra-large loads, expect 2 packets; include clear safety storage text and child-protection warnings prominently on pack (see Better Homes & Gardens detergent use and safety).

- If you plan cross-compatibility messaging with auto-dispensers, align your “loads per packet” with the dispenser’s concentration setting guidance so consumers can match expectations. Cleaning Supply Review looks for clear “1 packet = 1 medium load” instructions in our reviews.

Calculate dose per load

- Formula: oz per load = packet fluid ounces ÷ intended number of loads (recognized by washer manufacturers; see the Whirlpool concentration guidance).

- Worked examples:

- 1.00 fl oz ÷ 1 load = 1.00 oz/load (≈29.6 mL/load)

- 0.75 fl oz ÷ 1 load = 0.75 oz/load (≈22.2 mL/load)

- 30 mL ÷ 1 load = 1.01 oz/load

- 45 mL ÷ 2 loads = 22.5 mL/load = 0.76 oz/load

- If fill varies, document min–max oz/load to understand the range that will influence the final concentration category and labeling. Cleaning Supply Review standardizes on oz/load for cross-brand comparisons.

Map dose to an industry concentration category

Use Whirlpool’s widely referenced mapping; round to the nearest standard:

- 2X = 1.50–2.49 oz/load

- 3X = 0.90–1.49 oz/load

- 4X = 0.70–0.89 oz/load

- 5X = 0.50–0.69 oz/load

- 6X = 0.30–0.49 oz/load Higher “X” means a smaller per-load dose. Both labels and any machine concentration setting must match to avoid over/under-dosing (see the Whirlpool concentration guidance). Cleaning Supply Review standardizes on this Whirlpool map to keep labels and auto-dispensers aligned in testing.

Compact examples (1 packet = 1 load)

| Packet fill (mL) | Packet fill (fl oz) | Oz/load | Category |

|---|---|---|---|

| 30 | 1.01 | 1.01 | 3X |

| 22 | 0.74 | 0.74 | 4X |

| 16 | 0.54 | 0.54 | 5X |

| 12 | 0.41 | 0.41 | 6X |

Adjust for machine type, water hardness, soil level, and load size

- Machine type: HE washers use less water and typically need lower doses; many bulk auto-dispensers require you to input the detergent’s concentration once, and the setting persists until changed (see the Maytag bulk dispenser settings).

- Water hardness & soil: Hard water and heavy soil may need modest dose increases; soft water and light soil need less. Simple measuring aids (caps/scoops/markings) help prevent mis-dosing (see All Seasons Garment Care dosage tips).

- Load size: One pod usually covers a medium load; large to extra-large loads may require two, per consumer guidance and safety labeling (see Better Homes & Gardens detergent use and safety). In our tests, calibrating for these factors prevents avoidable over- or under-dosing.

Validate in lab and real-world wash tests

- Run standardized wash tests spanning HE and standard machines, soft/medium/hard water, cold/warm/hot cycles, and oily/protein/particulate soils. Track cleaning, sudsing, residue, and visible outcomes; iterate dose until targets are met (see All Seasons Garment Care dosage tips).

- Optimization loop: If cleaning is weak, treat the product as a lower concentration (increase delivered dose). If suds are excessive, treat it as a higher concentration (reduce dose)—this mirrors washer guidance on adjusting concentration to improve results (see the Whirlpool concentration guidance).

- Practical templates:

- Step-through: Set hypothesis dose → Test across conditions → Score metrics → Adjust dose/category → Re-test → Lock spec.

- Scorecard: Oils, proteins, particulates (Pass/Borderline/Fail) × Cold/Warm/Hot + notes for suds height and residue. Cleaning Supply Review combines structured lab runs with homeowner trials to verify real-world usability.

Confirm packaging, dissolution, and stability performance

- Dissolution: Verify rapid film dissolve and complete release across cold/warm/hot and varied agitation; pods must not be punctured and should dissolve without residue on fabrics or the drum (see The Spruce detergent dosing basics).

- Manufacturing QC: Monitor fill accuracy, pH, and viscosity, and use equipment compatible with a wide viscosity range to avoid under/overfill and stratification (see Advanced Dynamics filling and QC for detergents).

- Formulation levers: Balance low-suds surfactant systems (e.g., anionic with amphoteric co-surfactants) and builders for HE compatibility, viscosity control, and rinse clarity (see the Yeserchem formulation guide; see HAPPI formulating detergents). Cleaning Supply Review flags slow-dissolving films and variable fills as quality risks.

Safety, labeling, and consumer instructions

- Dosing clarity: State “Use one premeasured pack per medium load; add a second for large or extra-large loads.” Include HE-specific callouts and avoid vague capful language for pods.

- Handling and storage: Do not puncture or handle with wet hands; close packages securely, use child-resistant closures, and store out of sight and reach—pods have been linked to pediatric poisonings and eye/skin injuries (see Better Homes & Gardens detergent use and safety).

- Auto-dispensers: Instruct users to set the washer’s concentration to match your label; note that the setting remains until changed (see the Maytag bulk dispenser settings). Cleaning Supply Review prioritizes plain-language dosing and visible child-safety warnings in product evaluations.

Troubleshooting and iteration guidelines

- Poor cleaning: Increase delivered dose or reclassify to a lower “X” (machine dispenses more at a lower concentration setting), per washer guidance (see the Whirlpool concentration guidance).

- Excess suds or residue: Reduce dose, consider a higher “X,” and rebalance for low-suds HE performance. On-pack visuals and measuring aids reduce overdosing (see All Seasons Garment Care dosage tips).

- Incomplete dissolution: Reassess film selection, seal integrity, product viscosity, and cold-water performance; verify filling accuracy and that production equipment handles your viscosity window (see Advanced Dynamics filling and QC for detergents). This is the same loop Cleaning Supply Review uses when benchmarking packet formulas.

Frequently asked questions

What dose per load is typical for liquid laundry packets?

Most single-dose packets are designed for one medium load; use one pack and add a second for large or extra-large loads. Cleaning Supply Review recommends matching this with the product’s listed concentration.

How do HE washers change the correct concentrate level?

HE machines use less water and favor low-suds, concentrated detergents; set the washer’s dispenser to the correct concentration and follow the “one pack per medium load” guidance to prevent residues or oversudsing. Cleaning Supply Review advises keeping the same setting until results suggest an adjustment.

How should I adjust dosing for hard water or heavy soil?

Hard water and heavy soil often warrant a modest dose increase, while soft water and light soil need less. Cleaning Supply Review suggests starting at the labeled dose, then adjusting in small steps.

What happens if the concentrate is too strong or too weak?

Too strong can cause oversudsing and residue—reduce dose or classify at a higher X level. Too weak can reduce cleaning—increase dose or classify at a lower X level; Cleaning Supply Review uses the Whirlpool map for these calls.

How do I verify packets dissolve fully without residue?

Test in cold, warm, and hot cycles at different agitation levels; a well-formulated pod dissolves quickly and rinses clear with no film left behind. Cleaning Supply Review looks for full dissolution in under a minute in cold water during evaluations.